Blog LEAN

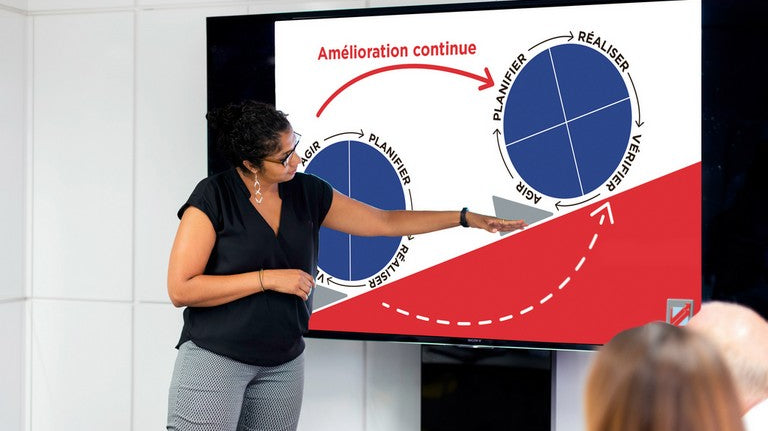

What is Continuous Improvement?

An Exploration of Kaizen, the Deming Wheel and the PDCA Method Continuous improvement is an essential concept in the field of Lean Manufacturing and Lean Management. It is based on...

Lean or 5S? Understanding differences and complementarities

In the world of process improvement and quality management, two approaches often stand out: Lean Management and the 5S method. While they share similar goals of efficiency and elimination of...

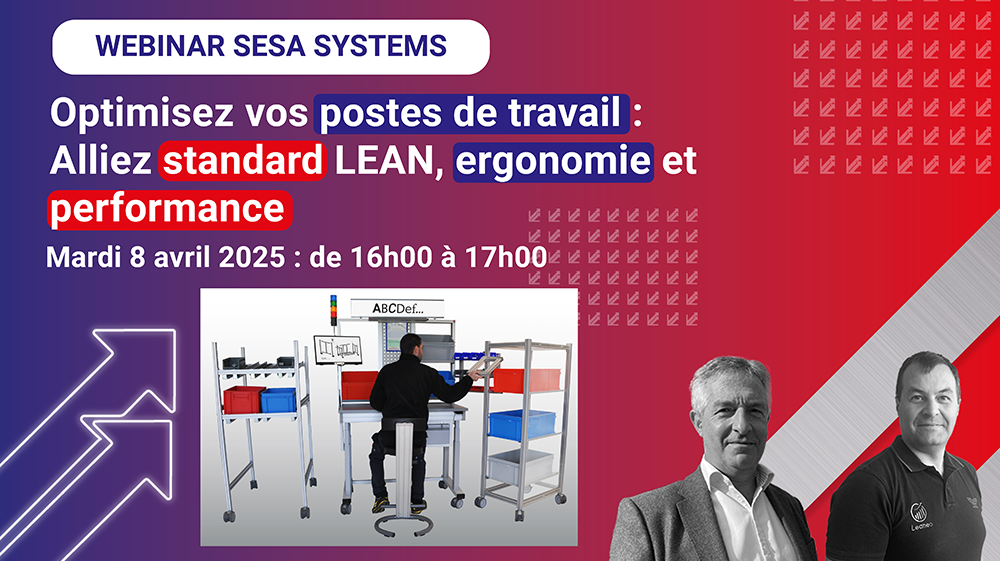

Participez à notre prochain webinar en direct

📣 Inscrivez-vous à notre prochain Webinar sur le LEAN ! Optimiser vos postes de travail : Alliez standards LEAN, ergonomie et performance 📅 Mardi 8 avril 2025 à 16h00 Au...

Participez à notre atelier LEAN

SESA SYSTEMS organise dans son ACADEMY un atelier LEAN. Le thème abordés est : Comment pérenniser la démarche LEAN et le management visuel ?📅 Jeudi 16 novembre 2023de 9h00 à 12h00...

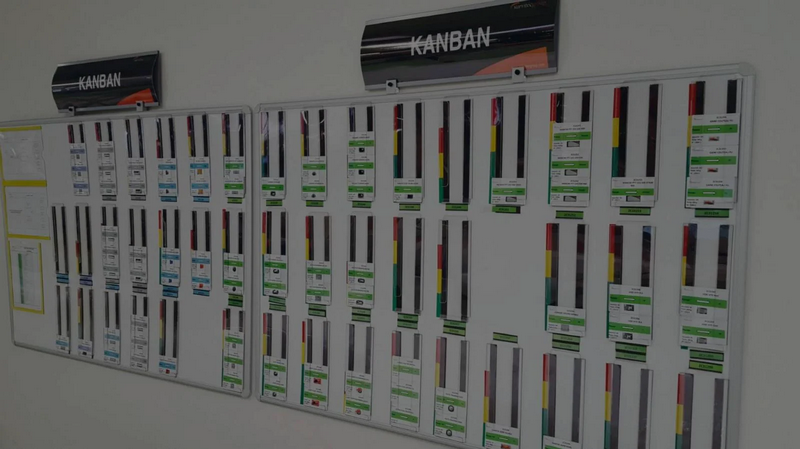

Organize production using the KANBAN planning method

As businesses grow, their production also increases. If processes, facilities, and organisation don't keep pace, this can lead to disorganised workflows, missed deadlines and reduced productivity. Fortunately, there is a...

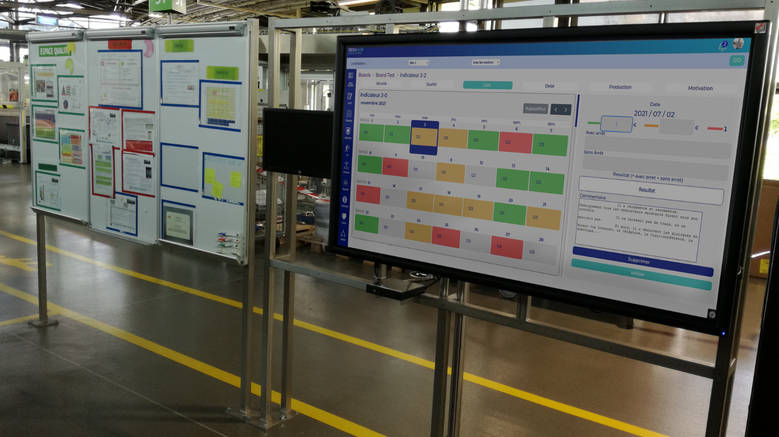

Using Visual Management to visualise indicators on a board

Visual management is a management technique that uses boards and indicators to visually present a company's performance. This method enables teams to work more efficiently, identify problems quickly and make...

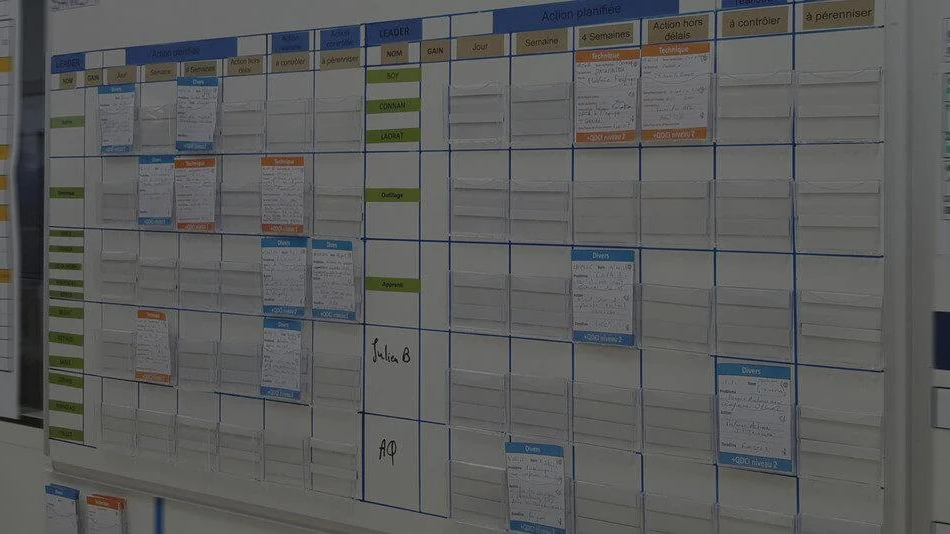

How do you develop and implement continuous improvement?

What is continuous improvement - Kaizen Continuous improvement is a method of optimising a company's processes and results by reducing errors and malfunctions. This practice consists of identifying problems, finding...

How to measure and apply LEAN methods in the workshop?

In today's high-speed world, production facilities are under constant pressure to optimise their production processes and reduce waste. This is where the LEAN approach comes in. The Lean approach aims...

How does 5S work?

Explanation of the 5S method Increasingly present in many organisations, the 5S method allows the optimisation of the environment, conditions and working time through the optimisation of processes and changes...

How to promote the LEAN Manufacturing among operators?

What is LEAN Manufacturing and what does it mean? To fully understand the issues involved in raising operators' awareness of LEAN Manufacturing, it must be defined and understood. LEAN Manufacturing...

Pourquoi mettre en place la méthode 5S ?

La méthode 5S est originaire du Japon et a été développée par l'industrie automobile japonaise au cours des années 1950 et 1960. Cette méthode a été adoptée par de nombreuses...