Jidoka: LEAN production error detection system

Jidoka, an Automatic Production Error Detection System

Jidoka, a Japanese word which loosely translates "the transfer from man to machine," - was invented by Sakichi Toyoda, the founder of Toyota. The objective of Jikoka is to set up automatic non-conformity detection systems. Over time, this method is increasingly used to reduce the number of operators required to monitor a machine.

DOWNLOAD THE LEAN ENTERPRISE CATALOGUE

Improving Lean Manufacturing with Jidoka

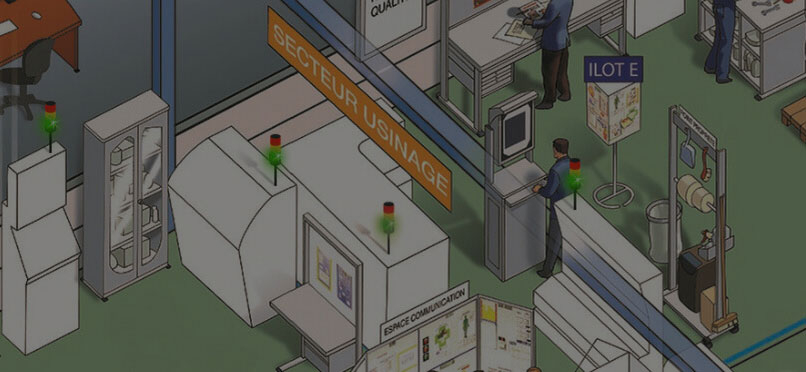

The relative intelligence of Jidoka is one of the pillars of TPS (Toyota Production System), but also a pillar of Lean Manufacturing. Much like the just-in-time method, Jidoka focuses on operations. It allows problems to be solved as soon as they occur in the production process, avoiding the creation of defective products. This solution makes it possible to be more productive, reduce the waste of time and eliminate the 7 types of waste. The main concepts of Jidok, referred to as the 6 Sigma, focuses on defect removal.

Quality Anomaly Management in the Lean Manufacturing Chain

The TPM method aims for zero defect, which is the first step in launching continuous improvement or progress initiatives for industrial groups. Total Productive Maintenance allows the optimization of machine productivity, making it possible to eliminate the non-quality of the machine. However, TPM is not the only tool to eliminate problems of non-quality.

The Poka-Yoke, is a device put in place to reduce errors and unintended problems that most often occur with the mounting, assembly or connection of parts. The reduction of errors is amplified by the 5S method, which promotes an organized work environment, arranged to improve the performance of the workstation and the quality of production.

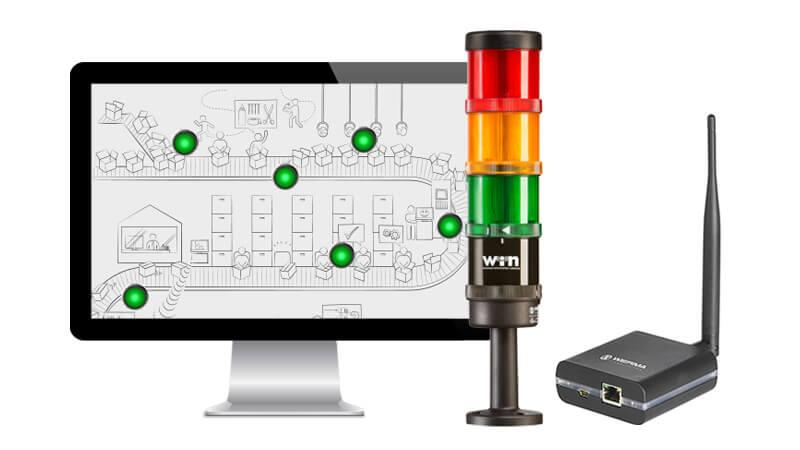

The sooner a problem is detected, the sooner it can be solved and the more operational the production line will be. In order to detect and eliminate anomalies, defects and quality problems as quickly as possible, production lines can install an Andon system. The Andon system is a modular light or sound column that signals the status of a machine, plant or process. To effectively solve these anomalies quickly, companies utilize the QRQC (Quick Response Quality Control) approach.

Essential Tools to Implement the Jidoka Method

Discover SESA SYSTEMS products to improve processes and prolong production efficiency.

DOWNLOAD THE LEAN ENTERPRISE CATALOGUE

Optimize your processes and improve your performance !

Discover all the concrete applications, tools to implement as well as our advice on our areas of expertise.

Need more information?

Do not hesitate to contact us if you would like more information or customized support.

Our experts are at your disposal.