Blog LEAN

Implementing Lean Manufacturing in Production: Steps, Challenges, and Tips

Introduction: Why switch to Lean production today? In an increasingly demanding industrial context, where every form of waste directly impacts performance, Lean Manufacturing stands out as a key driver of...

What are the benefits of digital visual management?

Companies are turning a corner in their digital transformation. This means that they are starting to include digital and connected solutions in their services. This includes the digitalisation of visual management, but also the...

What is Industry 5.0?

The Fifth Industrial Revolution: Industry 5.0 Industry 5.0 is the fifth stage in a series of industrial revolutions that have transformed production methods and global economic models. To better understand...

How to Improve Production Line Performance: Solutions and Best Practices

In an increasingly competitive industrial environment, the efficiency of production lines is a strategic lever for boosting profitability, quality, and agility. Continuous improvement is no longer an option—it’s a necessity...

Occupational therapy and industry: practical solutions to improve health and well-being at work

Occupational therapy and industry: discover practical solutions to prevent MSDs and improve workplace health through appropriate ergonomic equipment.

How to Avoid Production Delays? 5 Keys to Optimize Planning

Production delays can pose a major challenge for any industrial company manufacturing products. They lead to increased costs, dissatisfied customers, and can negatively impact market competitiveness. However, rigorous and optimized...

Why Implement Digital Visual Management for an Industrial Production Team?

Digital visual management is a modern approach that transforms the management of industrial production teams by enhancing communication, productivity, and quality. Integrating this methodology offers numerous advantages specific to the...

Why implement the 5S method?

The 5S method is originally from Japan and was developed by the Japanese automobile industry in the 1950s and 1960s. It has been adopted by many other industries in Japan...

How to Train and Raise Awareness Among Your Teams About the 5S Method?

The 5S method, derived from Lean Manufacturing, is essential for establishing an efficient, secure, and well-organized work environment. Equally applicable to office and production settings, it is based on five...

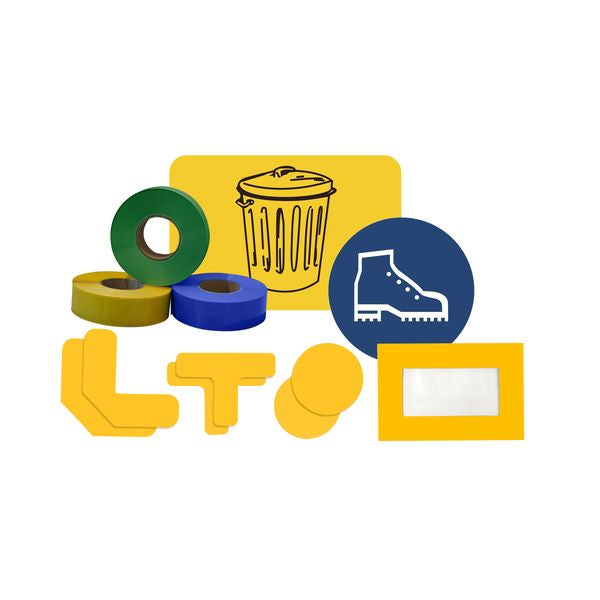

How to Implement Floor Marking in an Industrial Environment?

Floor marking is an essential component of industrial production settings. Rooted in the principles of Visual Management and Lean Manufacturing, it organizes warehouses and workspaces, enhances productivity, and most importantly,...

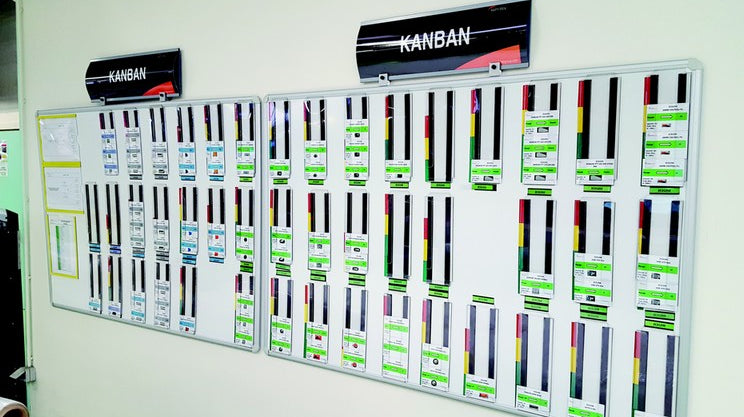

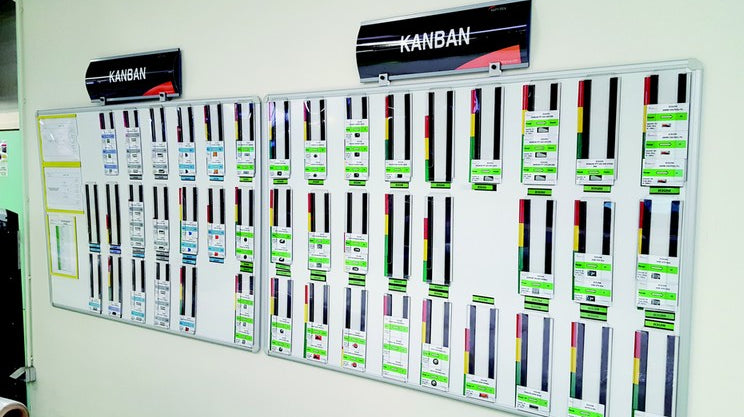

How to Use the Kanban Method?

The Kanban method, originating from Toyota's production system in the 1940s, is a workflow management approach aimed at optimizing team efficiency and productivity. It relies on task visualization and limiting...

How to Improve Work Processes with LEAN Methods?

What is LEAN? In a world where competition is increasingly fierce and companies are constantly seeking to maximize their efficiency to better meet customer needs, LEAN emerges as a powerful...