Introduction: Why switch to Lean production today?

In an increasingly demanding industrial context, where every form of waste directly impacts performance, Lean Manufacturing stands out as a key driver of operational excellence. Cost reduction, improved quality, enhanced flexibility… the benefits are numerous for production, QHSE, methods, and industrial management teams. This original production method developped by Toyota can make a real difference.

But the real challenge lies in implementing this technique effectively.

This article guides you through the key stages needed for Lean Manufacturing deployment, highlights common challenges faced on the shop floor, and shares practical advice for a successful transformation. Along the way, discover how SESA SYSTEMS solutions can accelerate and secure this process.

Step 1: Understand the Fundamentals of Lean Manufacturing

Before anything else, it is essential to build a shared Lean vision with your teams. Lean aims to eliminate waste (muda), optimize flows, and place people at the heart of performance.

📌 Key objectives:

-

Create value for the customer

-

Continuously improve processes

-

Involve operators in field improvement initiatives

Recommended tools: training programs, visual displays of Lean principles, and the 7 wastes boards.

Step 2: Conduct an Initial Diagnosis

Every Lean implementation starts with an assessment. The goal is to identify bottlenecks, time losses, unnecessary movements, and recurring errors.

📌 Effective methods:

-

Value Stream Mapping (VSM)

-

Waste analysis

-

On-site observation

Suitable SESA SYSTEMS tools:

-

Ergonomic observation stations

-

Flow analysis boards

-

Visual management software

Step 3: Launch a Pilot Project

To engage teams, start small: a single production line, cell, or workshop. A pilot project helps you test, adjust, and demonstrate Lean’s benefits.

📌 Pilot action examples:

-

Implementing 5S

-

Reducing changeover times (SMED)

-

Standardizing a workstation

👉 SESA SYSTEMS’ modular industrial furniture enables optimal organization from the very start.

Step 4: Scale Up Progressively

Once the first results are achieved, the next goal is to replicate best practices across the plant. This requires strong governance, clear KPIs, and hands-on support.

📌 Keys to success:

-

Structure governance with Lean routines (TOP 5, QRQC, etc.)

-

Develop visual management

-

Track performance gains: quality, lead time, productivity

Recommended solutions:

-

Lean performance boards

-

Magnetic supports for KPIs

-

Interactive digital terminals for continuous improvement

Challenges and Practical Solutions

1. Resistance to Change

Old habits die hard in production. To succeed, explain, train, and involve your teams.

✅ Tip: Set up visual suggestion boards where operators can share improvement ideas.

2. Lack of Time or Resources

Daily operations often slow down Lean initiatives.

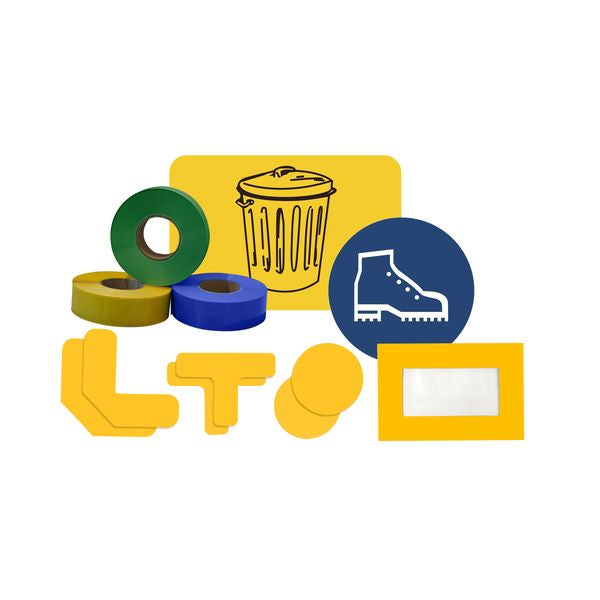

✅ Tip: Structure your efforts around short, visible, and measurable projects. Use simple, accessible tools to boost efficiency (e.g., 5S kits, floor marking, visual management).

3. Difficulty Sustaining Gains

A successful Lean project doesn’t guarantee long-term results without consistent follow-up.

✅ Tip: Rely on regular team rituals and standardized visual management (5S audits, monitoring boards, evolving signage, etc.).

Practical Tips for a Successful Lean Implementation

🚀 Focus on ergonomics – a well-designed workstation supports standards, reduces MSDs, and boosts efficiency.

🛠️ Standardize with visual tools – instructions, indicators, checklists… make adoption easy for everyone.

📊 Drive performance using modular boards – QCD indicators, action tracking, feedback collection.

📲 Go digital when possible – SESA SYSTEMS connected solutions pave the way to the Factory of the Future.

SESA SYSTEMS – Your Partner for a High-Performance Lean Production

For over 30 years, SESA SYSTEMS has supported manufacturers in their Lean transformation. With a catalog of 2,800 products dedicated to industrial organization, you have concrete solutions for every step of your journey:

✔️ Ergonomic, modular workstations

✔️ Visual management tools: Lean boards, magnetic supports, floor signage

✔️ Digital improvement tools: interactive terminals and dedicated software

🌍 Available in France and worldwide – 100% in-house manufacturing.

Conclusion: Take Action with Tools Designed for Lean

Implementing Lean Manufacturing is a strategic lever for any industrial company striving for sustainable performance. With a structured approach, progressive team engagement, and the right tools, success is within reach.

📩 Discover our complete range of Lean solutions

📞 Contact our experts for personalized support.