TPM: Method and approach to increase productivity

Zero Downtime Goal with the TPM Method – Total Productive Maintenance

Are you facing significant losses that come with costs you no longer want to bear? Looking to increase output and improve quality without additional investment?

Choose the TPM method – Total Productive Maintenance – a strategy designed to increase the productive uptime of your production equipment by reducing downtime and breakdowns. While boosting productivity, it also enhances quality and other key performance indicators. This approach is a core pillar of steps of Lean Manufacturing.

DOWNLOAD THE TPM MANUAL

What is TPM? - Definition of the TPM Maintenance Technique

TPM – Total Productive Maintenance is a strategic practice aimed at building a company culture that improves the efficiency of the production system. It enables a gradual transition from reactive (corrective) maintenance to preventive, and even predictive maintenance in specific cases.

The ultimate goal is to achieve absolute reliability, leading to zero breakdowns, zero defects, and zero accidents in production.

This approach originates from a strong commitment by top management to:

- Establish a culture of Continuous Improvement

- Engage all employees by making them accountable

- Improve QUALITY / COST / DELIVERY performance

- Enhance equipment effectiveness (referring to productivity, efficiency, and operational performance)

-

TOTAL

Address all aspects of maintenance and involve everyone in the process.

-

PRODUCTIVE

Perform maintenance activities while continuing production, minimizing disruptions.

-

MAINTENANCE

Maintain equipment in optimal condition: repair, clean, lubricate — and dedicate the necessary time to do so.

History of TPM – Total Productive Maintenance

TPM evolved from the American concept of Preventive Maintenance (PM). It was developed in post-World War II Japan, believed to have originated in the factories of the Nippondenso group before being formalized by the Japan Institute of Plant Maintenance (JIPM).

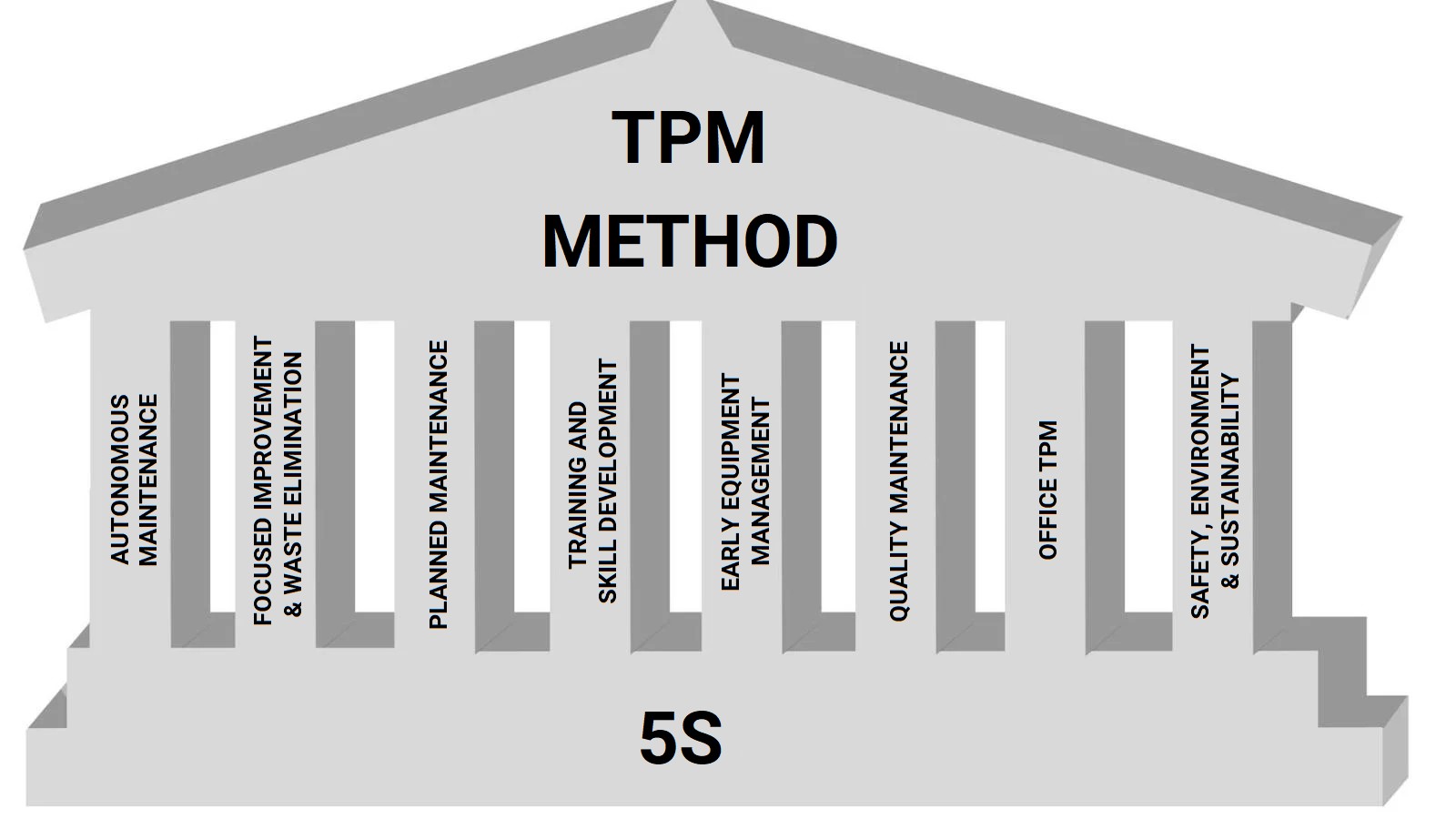

In 1989, the JIPM defined 8 pillars upon which a successful TPM strategy is built to achieve a high level of industrial performance. Today, TPM is a registered trademark of the JIPM, which awards the prestigious "TPM Excellence Award" to companies that implement TPM in an exemplary way. This certification is highly respected in the Japanese industry and recognized internationally.

The key difference between TPM and PM lies in its participative approach. TPM emphasizes active involvement of teams and operators, whose hands-on knowledge of their machines makes them essential contributors to effective maintenance.

The 8 Pillars of TPM

In 1989, JIPM established eight foundational pillars that support a TPM strategy aimed at industrial excellence.

These pillars are generally divided into two groups of four:

-

Group 1: Enhancing Production System Efficiency

Autonomous Maintenance (operators take responsibility for routine upkeep of their equipment), Focused Improvements (targeted actions to eliminate waste), Planned Maintenance (proactive scheduling of maintenance tasks), Skills and Training (enhancing technical knowledge and know-how).

-

Group 2: Extending TPM Beyond Production

Safety, Health, and Environment (ensuring safe, clean, and ergonomic workspaces), Quality Maintenance (maintaining product quality through machine condition), Early Equipment Management (integrating maintainability into equipment and product design), Administrative & Support Functions (applying TPM principles to offices and support departments: TPM in the office).

Some sources and experts present TPM as a building: the 5S methodology forms the foundation, and the 8 pillars support the structure. The strength of the whole depends on the robustness of the 5S practices. A minimum number of pillars can support the structure effectively. Conversely, even if some pillars are weak, the TPM system can still function. Therefore, it is not necessary to implement all eight pillars simultaneously or equally to achieve meaningful results with TPM.

Pillar 1: Autonomous Maintenance

This pillar significantly enhances the skill level of production operators, enabling them to independently handle routine maintenance tasks and minor repairs. The first crucial step is a deep cleaning of the machine, which helps uncover hidden anomalies ("cleaning to inspect"). The goal is to foster responsiveness in the event of malfunctions and develop team autonomy. Operators become more involved, responsible, and motivated—while freeing expert maintenance technicians to focus on preventive actions and continuous improvement.

Pillar 2: Focused Improvement & Waste Elimination

This method involves a deep understanding of how the equipment operates and analyzing deviations that lead to efficiency losses. The objective is to eliminate all forms of waste and efficiency loss at the root. Root cause analysis is key to permanently resolving breakdowns. Improvement efforts are guided by indicators such as OEE (Overall Equipment Effectiveness) and targeted performance metrics.

Pillar 3: Planned Maintenance

Planned maintenance focuses on preventive and condition-based maintenance. Activities are scheduled based on failure rates. Techniques such as FMEA (Failure Modes and Effects Analysis) are used to anticipate failures and plan interventions proactively. The aim is to reduce or eliminate unexpected breakdowns, lower maintenance costs, avoid unplanned overtime, and better manage spare parts.

Pillar 4: Training and Skill Development

Implementing new work methods requires developing new skills. This pillar involves knowledge management, starting with a skill assessment, identifying training needs, and planning structured learning paths. Mentorship programs are encouraged, where experienced staff train newcomers. Training is adapted to the level of involvement: from general awareness for all operators to in-depth coaching for autonomous teams and coordination committee members.

Pillar 5: Early Equipment Management (Product & Equipment Design)

The goal is to avoid repeating past mistakes and to apply lessons learned from problem-solving initiatives to new equipment design. Improvements in design, usability, and maintainability are integrated from the start of development. By applying this approach, startups and debugging times can be greatly reduced, resulting in lower implementation costs.

Pillar 6: Quality Maintenance

This pillar ensures product quality by stabilizing both equipment and processes. It seeks to eliminate the causes of defects, ensuring every minute of production yields conforming products. Key actions include:

- Systematic measurement to ensure the equipment does not cause quality issues

- Verification that measured values remain within tolerance limits

- Monitoring trends to predict and prevent defects

- Eliminating all abnormal deterioration, allowing only normal wear

Pillar 7: Office TPM (Improving Administrative & Support Functions)

This pillar applies TPM principles to administrative and support departments (warehouses, maintenance offices, etc.). The goal is to extend the successes seen in production through tools like 5S, improving service efficiency in areas that directly impact production. Focus areas include quality, cost, quantity, and delivery performance in non-manufacturing functions.

Pillar 8: Safety, Workplace Environment & Sustainability

Aligned with sustainable development principles and current regulations, this pillar targets the elimination of all potential hazards related to:

- Workplace safety, especially in high-incident areas

- Environmental protection

- Working conditions, aiming to create a clean, safe, and ergonomically sound environment

TPM Objective

The Goal of Total Productive Maintenance

Total Productive Maintenance (TPM) is a machine-centered approach and increasingly represents the first step in any performance improvement initiative.

To implement it effectively, a company must first eliminate randomness and unexpected disruptions from its production activities.

A high-performing facility relies on reliable and available production equipment.

TPM enables clear and visual representation of key indicators and performance-influencing factors through graphs, Pareto charts, and trend curves. These visual tools generate detailed reports based on TPM-specific criteria, allowing customized analysis tailored to specific timeframes or resource constraints.

The purpose of this data analysis is to identify underperformance through OEE (Overall Equipment Effectiveness)—a central KPI in TPM. OEE evaluates equipment effectiveness by combining availability, performance, and quality. This helps focus improvement efforts on root causes of inefficiency and quickly increase overall equipment effectiveness.

The 3 Core Objectives of TPM Systems:

- Minimize equipment underutilization, which leads to significant production and financial losses

- Extend equipment life through structured and consistent maintenance practices

- Improve organization, safety, and operational efficiency to achieve the highest levels of performance.

Benefits of the TPM Method – Direct Results

- Establishment of maintenance routines and cleanliness standards at workstations and their surrounding areas

- Implementation of visual management systems

- Elimination of waste, including time and materials

- Enhanced equipment monitoring and traceability

- Overall improvement of the work environment

Behavioral Benefits of the TPM Approach

- Involve and communicate with everyone, not just managers or supervisors

- Challenge existing habits and routines

- Maintain equipment in optimal condition

- Sustain results over the long term and pursue continuous improvement

- Foster collective responsibility by respecting shared rules and commitments

Minimizing Losses Through TPM

When observing a machine throughout a workday, it becomes clear that it doesn't operate continuously during the plant’s full opening hours. Certain operations require it to stop, or at least enter non-productive phases—which are directly associated with losses.

TPM identifies six major sources of loss:

- Unplanned downtime

- Changeovers

- Micro-stops

- Reduced operating speed

- Defects during production

- Defects during startup

These losses introduce the concept of Gross Operating Time.

During the gross operating time, one might expect the output to equal this time divided by the machine's nominal speed. However, real-world production data proves otherwise. Performance is affected by various disruptions: breakdowns, process drift, micro-stops… and actual speed is often—if not always—lower than the nominal speed.

Gross operating time minus time lost = Net operating time.

But even then, not all produced parts are usable. Only good parts can be sold to customers, which brings us to the Useful Operating Time.

The diagram below shows the proportion of really useful time in relation to total opening time as a function of losses. With such waste, the profit needed to keep the company going is not guaranteed! It's worth noting that each “loss” has its cause in an area that will be of interest to maintenance. To increase productivity, all these losses must be reduced. Thanks to OEE (Overall Equipment Effectiveness), it becomes possible to quantify losses and identify targeted improvement actions.

Total Available Time

➝ Actual Opening Time (minus unused factory capacity)

➝ Gross Operating Time (minus planned stops)

➝ Net Operating Time (minus unplanned stops, slowdowns, micro-stops)

➝ Useful Operating Time (minus defects and quality losses)

The Ideal Production System would then be:

- Zero breakdowns or unplanned stops

- Zero defects

- Zero accidents

In practice, this means:

- Keeping equipment in optimal condition: repair, clean, lubricate, and perform routine inspections

- Minimizing production disruptions

- Taking a comprehensive view of maintenance, involving all teams

Machine Performance Under the TPM Approach

To achieve high performance, a production site requires reliable equipment. That’s why TPM (Total Productive Maintenance) focuses primarily on the machine as the core of operational efficiency.

When a company decides to adopt a Just-In-Time (JIT) and Zero Inventory production model, it must ensure that its production system can meet customer deadlines without fail. This is only possible if the following conditions are guaranteed:

Machines and tools are fully available during the entire planned production time

Launched quantities are achieved, and only good-quality products are produced

Planned cycle times are accurate and consistently met

To meet these critical expectations, the company must eliminate random failures and unexpected events from its production operations. This requires a well-trained team, structured techniques, and robust problem-handling processes. The first step is process reliability—stabilizing operations through consistent procedures and preventive actions. Once reliability is in place, it becomes possible to implement autonomous maintenance programs, enabling operators to take responsibility for routine care of their machines.

When to Implement TPM (Total Productive Maintenance)?

TPM should be applied to equipment where the cost of underperformance exceeds the cost of achieving optimal performance. Its implementation must follow a structured and rigorous methodology, rolled out in clearly defined stages.

The process should begin with a pilot project, which serves as a foundation for training first-level management, the area supervisor, and support functions such as methods and maintenance. Once tangible results are observed, TPM can be gradually rolled out across the entire site.

TPM is therefore a long-term commitment, requiring continuous effort, engagement, and cross-functional collaboration to ensure lasting success.

Succeeding with the TPM Method

The TPM (Total Productive Maintenance) approach improves the production capacity of technical resources by building a system that eliminates losses and waste, aiming for “zero accidents, zero defects, and zero breakdowns.” This technique is grounded in shopfloor involvement (Gemba) and real issues (Genbutsu) throughout the entire life cycle of the production system.

TPM requires the participation of all departments, not just production-related areas, but also engineering, development, marketing, and administrative services—at every level of the organization, from executives to operators.

The goal is to achieve “zero losses” by initiating improvement initiatives in small groups. Everyone involved should find value in the TPM approach—not necessarily financial, even if that’s often highlighted. In reality, deeper motivations often drive engagement.

One undeniable benefit for operators is the feeling that “it’s a relief to remove the stone from your shoe.”

That "stone" might represent routine frustrations, perceived attitudes from management, the feeling of not being heard, or difficulties in performing tasks under normal conditions (equipment issues, raw material inconsistencies, poor organization, or ergonomic challenges). It may also reflect the need to feel useful and empowered to solve problems.

Through TPM, equipment is protected, and production is optimized.

Game-Based Training for the TPM Method

Fun e-learning game for professionals

Average duration: 2h30

Based on the concept of a car racing journey inspired by the Game of the Goose, full of unexpected events and challenges, the goal is to eliminate all internal and external sources of production equipment malfunctions.

Don't wait any longer to train your employees in TPM through gaming!

TPM-PDCA-SUGGESTION Starter Kit: Instantly and easily develop a PDCA board, improvement proposals (suggestions), and a TPM (Total Productive Maintenance) framework for a pilot project following the game session.

Results: A collective, shared, and effective success.

DOWNLOAD THE TPM MANUAL

Optimize your processes and improve your performance!

Discover all the concrete applications, tools to implement as well as our advice on our areas of expertise.

Need more information?

Do not hesitate to contact us if you would like more information or customized support.

Our experts are at your disposal.